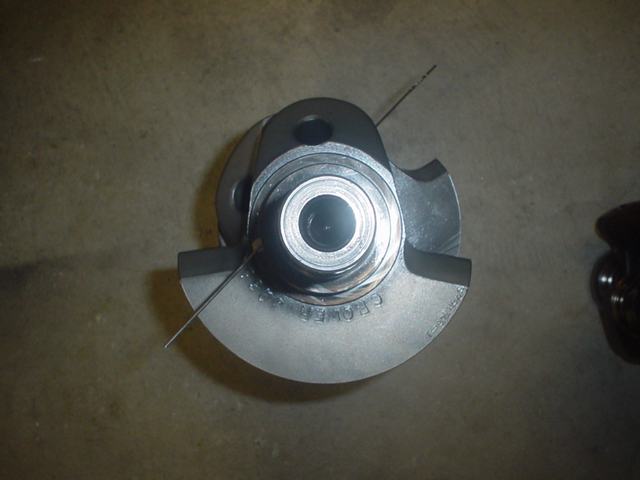

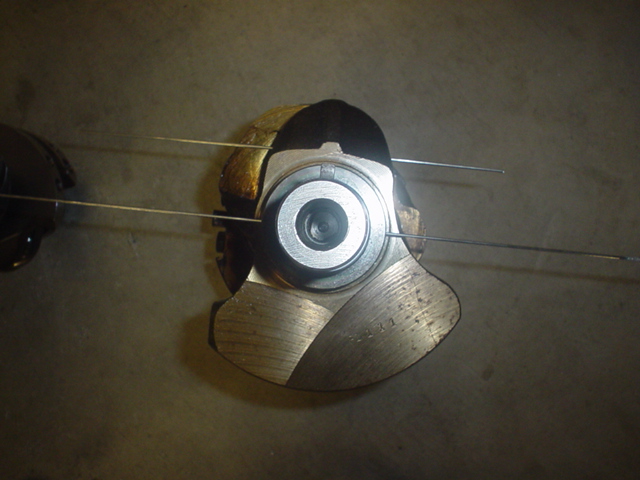

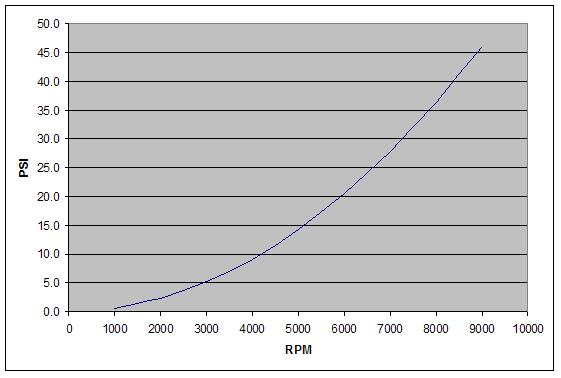

| The first two pics here show the different oil drilling from the main journal to the rod journal. The stock VG crankshaft is crossdrilled on both the main and the rod journals with a "T" intersection drilled on center to connect the two together. This may seem superior but it isn't when it comes to higher RPMs... with a stock drilling, the oil must overcome centripetal force to flow into the "T" drilling and on to the rod journal, this force increases exponentially as RPM increases (see graph below). The Crower drilling is known as "Chevy style" or "high-speed oiling" and is drilled as close to the being tangential to the main journal as possible and the pressure required to initiate flow to the rod journal is substantially reduced from stock (don't let anyone tell you they can modify a stock crank for high-speed oiling, plugging one side of a cross-drilling is nowhere near the same). Crower oil drilling

Stock oil drilling

Oil pressure required to overcome centripetal force at RPM

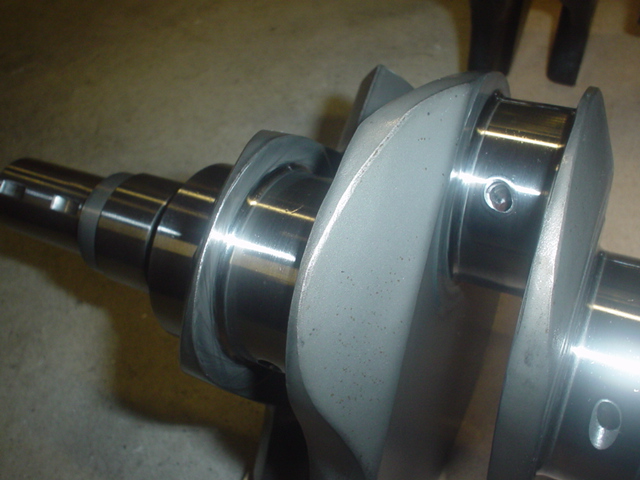

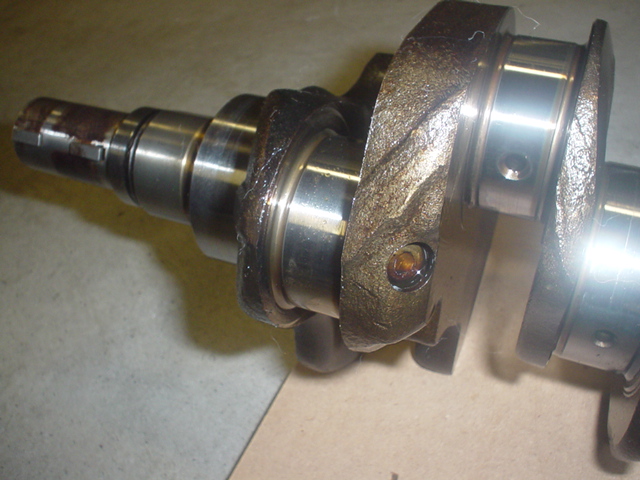

back stock, front Crower

Crower 5/32 radius. Rod journals are widened to allow radius to be tangential to bearing surface (to increase overlap/strength) and corresponding rods must be wider as well for proper thrust clearance.

Stock radius is undercut to achieve a large radius without impinging upon bearing width, the problem is this reduces cross-sectional overlap between journals and is a weak spot.

|